SIMSITE® Structural Composite Low Specific Speed Pump Impellers are Superior to Metallic Impellers, because they are engineered to increase efficiency and eliminate cavitation and recirculation problems that are inherent in low specific speed pump impellers! ImpellerStore is able to do this because our SIMSITE® Impellers are not cast or molded. Rather, SIMSITE® Impellers are machined on the outside as well as the inside on 5 to 8 axis machining centers.

Impellers that develop a low flow rate with a relatively high head are described as low specific speed impellers. A low specific speed impeller is one that is designed with a very large impeller diameter when compared to the impeller eye diameter. Low Specific Speed impellers have a geometry which has a larger outside diameter with relatively small, vane flow passages and exit ports.

The specific speed of an impeller influences the shape of the Head–Capacity Curve (HQ Curve). Low specific speed impellers generate a much flatter HQ curve from shut off to the operating point.

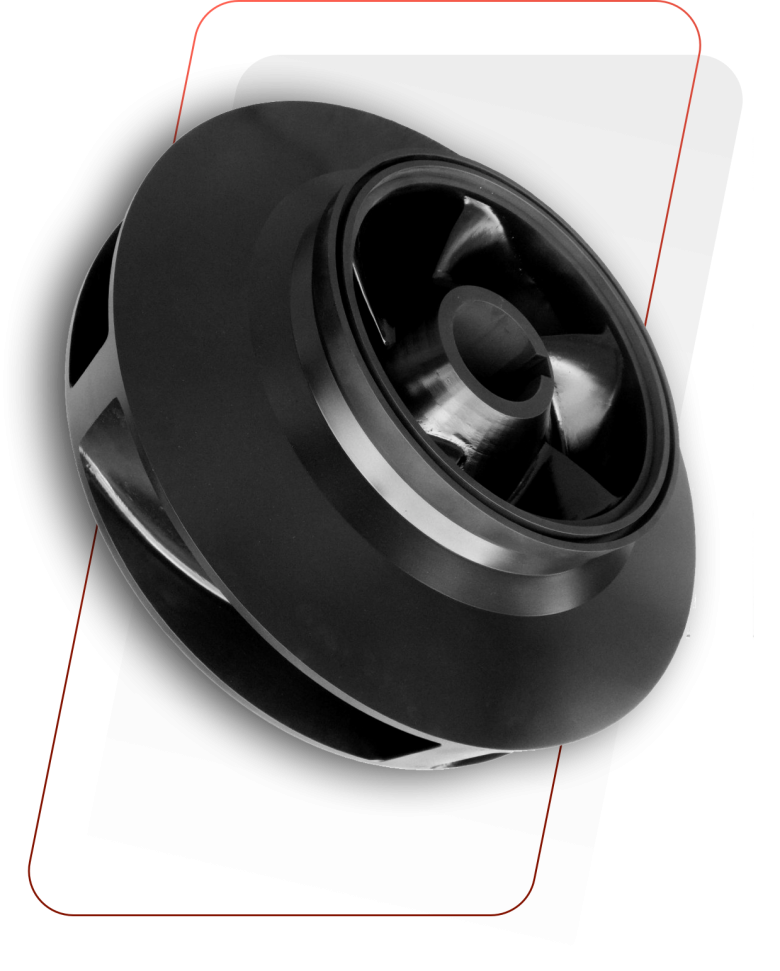

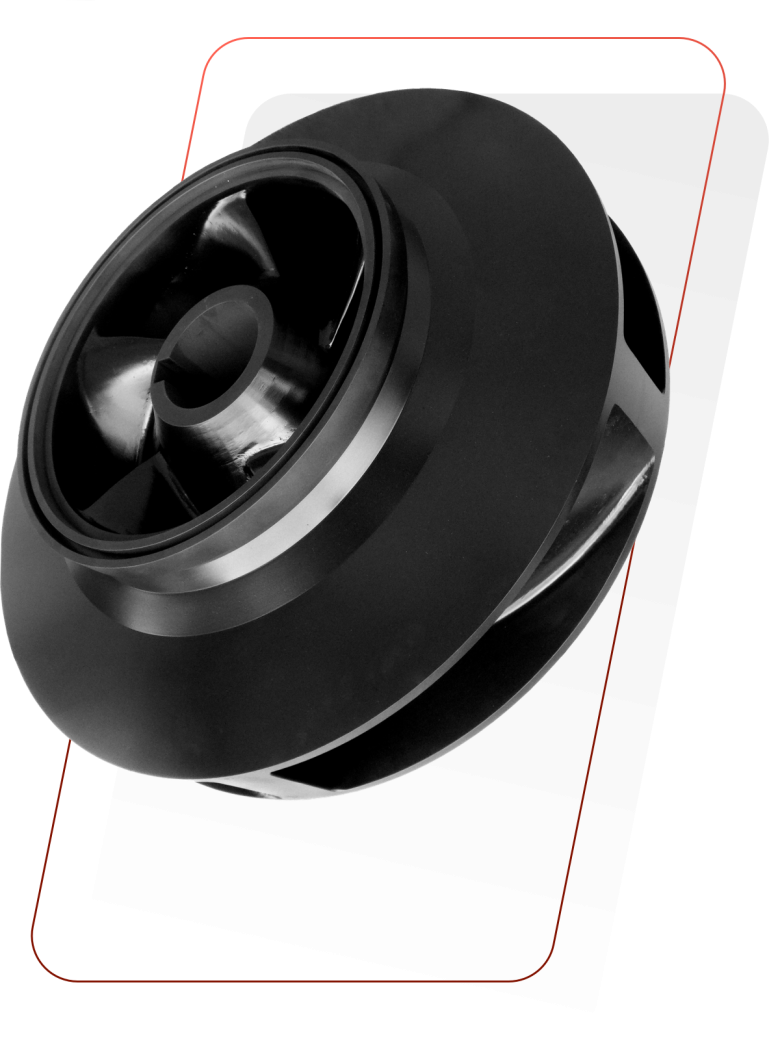

Typical Low Specific speed Metallic Impeller suffering from Discharge Recirculation Cavitation as well as Corrosion.

Typical Low Specific speed Metallic Impeller suffering from Discharge Recirculation Cavitation as well as Corrosion.

Although these low specific speed impellers can deliver a higher head they are much more susceptible to discharge recirculation which will destroy a metallic impeller in a very short period of time.

Fortunately, SIMSITE® Impellers are engineered to reduce or eliminate the effects of all types of cavitation. Because SIMSITE® Impellers are precision machined from solid blocks of the structural composite, the impeller vane geometry can be engineered utilizing CFD(Computerized Fluid Dynamics) techniques and programs to eliminate the vortexing and cavitation problems experienced by cast or molded metallic impellers.

SIMSITE® Engineered composite impellers & Casing Rings offer even greater savings, because they can be engineered to make the pump operating point the Best Efficiency Point (BEP) which significantly increases efficiency! (The farther away the pump operates from BEP, the lower the efficiency, and the higher the radial loading, movement and vibration.) The machined vane surfaces provide smoother surface finishes, which allows for a lower coefficient of friction with self-lubricating qualities. Machined Structural Composite Impellers & Rings are 5 to 6 times lighter than metallic impellers and run on tighter wear ring to casing ring clearances. This provides reduction in mechanical losses as well as volumetric losses.